For detailed information, other images and documents, please select individual articles from the following table.

GEFU® thread-rolling screw with Taptite 2000® thread, flat head with hexalobular drive

Dimensions according to DIN EN ISO 14583, stainless steel A2, plain, anti-friction coating

Register now and access more than 60,000 products

Variants

Register now and access more than 60,000 products

Call customer service: +43 50 8242 0

Prices for customers after login

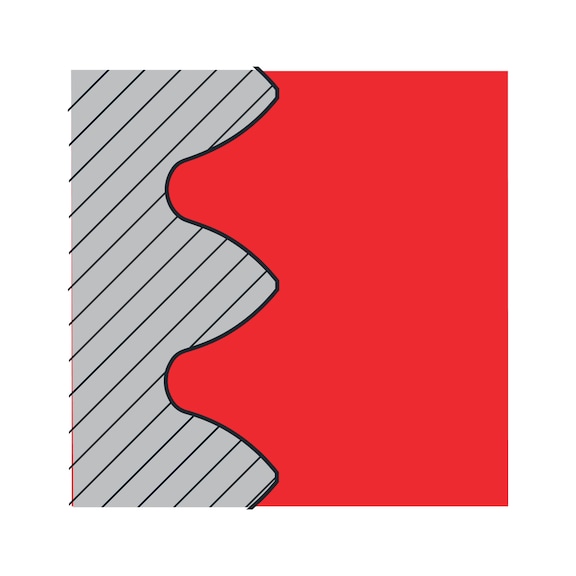

Self-tapping screws form a nut thread in cast blind holes, rim holes and drilled, lasered and punched sheet metal parts. Unlike thread cutting, self-tapping does not interrupt the material structure in the receiving thread. Instead, the material is displaced and strain-hardened.

Benefits:

Cost savings

- Eliminates thread cutting

Non-cutting thread formation

Low rolling torques with greater thread flank overlap

- TRILOBULAR shape of the core diameter combined with the radius profile of the thread flanks

High clamping force

- Due to low rolling torques

High load-bearing capacity

- Due to large thread flank overlap

- Due to strain-hardened counter thread (nut thread)

Protection against loss (reduced likelihood of screw working loose)

- Play-free and self-locking thread seating

The formed thread corresponds to a standard metric thread

- Where necessary, the GEFU screw can be replaced with a metric screw.

The suitability of the GEFU for the application or component in question must be determined through preliminary testing.

Examples of materials suitable for this type of non-cutting direct screw connection are ductile materials such as aluminium, zinc, brass, copper etc.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!