For detailed information, other images and documents, please select individual articles from the following table.

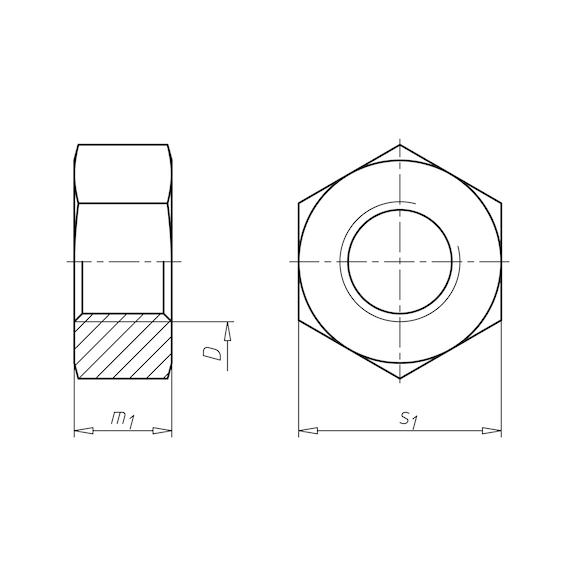

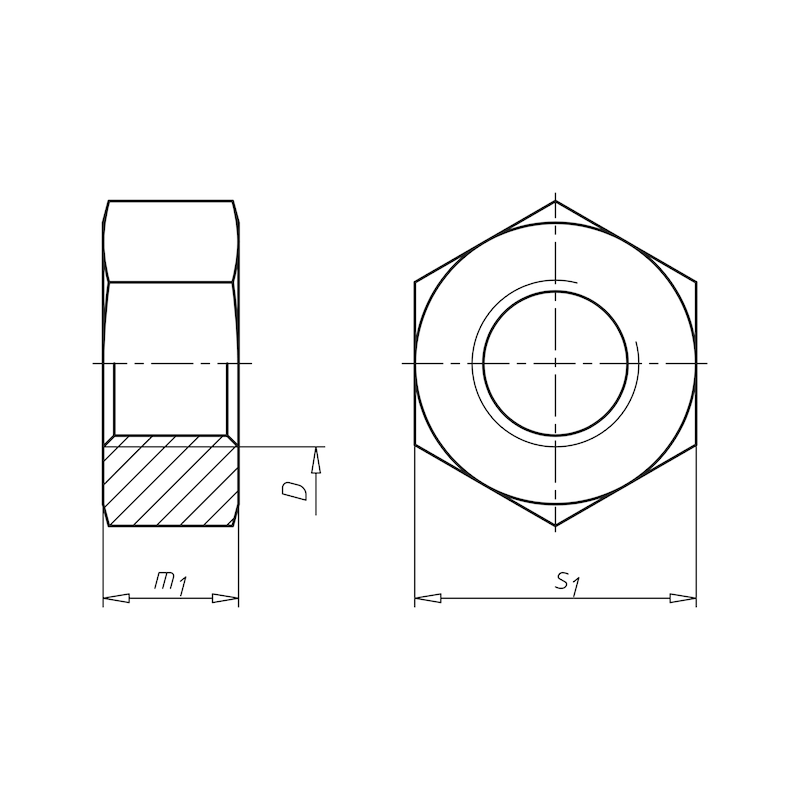

Hexagon nut DIN EN 14399-4, steel 10Z, hot-dip galvanised, for high-strength structural bolting assemblies

Register now and access more than 60,000 products

Variants

Register now and access more than 60,000 products

Call customer service: +43 50 8242 0

Prices for customers after login

- High-strength assemblies according to DIN EN 14399-4. For high-strength preloaded structural screw connections for metalworking

- HV system

- K1 class

- Strength class 10Z

- Hot-dip galvanised steel

- Lubricated with MoS2

"Only use complete sets (screws, nuts and washers) from one manufacturer." (extract from DIN EN 1993-1-8/NA:2010-12).

The design of supporting steel structures with high-strength fittings is regulated by DIN EN 1090-2 and DASt directive 024.

Due to batch traceability, these articles can only be purchased from and stored directly by the manufacturer and are therefore excluded from exchange or return!

Storage and transport:

Screws, nuts and washers are supplied in a hot-dip zinc-plated version with nut lubricated under process conditions. The female thread of the nut is not hot-dip zinc-plated and is protected against corrosion solely by the applied lubrication. Improper transport and storage conditions can result in corrosion of the female thread or to a change in the lubrication condition as supplied and the correlation between tightening torque and pretensioning force associated with this.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!